Supply Chain Management

Introduction

Discerning supply chain management as an exquisite part of stupendous growth is one

of the most paramount realizations that any firm must make. The true question stands,

why exactly do we have to believe that the supply chain management framework

is not secondary to a colossal growth strategy but works simultaneously with the

multitude of strategies that are embedded in the strategic growth framework? To

understand that, lets first understand what a supply chain is exactly:

Definition of Supply Chain

A supply chain is a network of nodes, each that is

assigned a responsibility which chooses itself from procurement, transformation or

transmission of materials and information all the way from the ultimate transmitter

(Raw material supplier) to the ultimate procurer (consumer).

Now that we know what a supply chain is, let us understand the notion of supply

chain management.

Definition of Supply Chain Management

Supply chain management is the art of

aligning the supply chain with respect to a strategy and facilitate point to point

connections between nodes of the supply chain optimally.

What is that strategy? Well, the strategy is the one that belongs to the strategic

growth framework, more specifically, that part of the strategic growth framework

which deals with the marketing framework. This explains why the supply chain

management framework goes hand in hand with many of the strategies that fit in the

strategic growth framework.

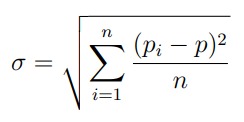

If we were to represent supply chain management mathematically, then we would

define it as:

Supply Chain Management = f(Strategy, Optimized Logistics)

Optimized logistics is something that we call logistics that incorporates mathematical concepts to reduce waste. So what is logistics?

Definition of Logistics Management

Logistics management is the art of planning

and delivering a strategy in real-time through facilitating entities befittingly.

The keywords ”delivering” and ”entities” are very very important. By delivering, we

mean, projecting the strategy into reality, and by entities, we mean the participating

nodes in our strategy.

Now that you have a good hold on what supply chain management is, we will

now talk about the history and evolution of supply chain management.

The History of Supply Chain Management

The term supply chain management was first coined by British logistician Keith R

Oliver in an interview in 1983. Although it was Keith who popularized this term, the

concept dates back to 1950's, right after world war 2. There are seven stages with

respect to the evolution of supply chain management:

- Misconception - 1950s

- Fragmentation - 1960s

- Consolidation - 1980s

- Integration - 2000s

- Automation - 2010s

We shall discuss each of these stages in detail.

Misconception

This stage was outright after the world war 2. At this point of time, industrialists

thought that the delivery stage of any product is just packaging and transportation.

So you make a product, pack it and just transport it. Packing is relatively a ”noisy”

concept for the context, i.e. packing protocols are pretty much covered in other areas,

so we will focus more on the transportation aspect.

Transportation is no joke, we can't say that transportation simply means moving

from one place to another. There is one factor that escalates the difficulty of

transportation: ”Optimism”. Firms really need to optimize transportation costs, for

which an enormous use of mathematical concepts is necessary. In this article, we

solve the general transportation problem:

Assume that there are m different ways of transport, t1, . . . , tm, n different destinations d1, . . . , dn and distance D1, . . . ,Dnand a total of T1, . . . , Tn goods to be transported to the n destinations. Using transport ti has cost ci per mile and gi number of goods need to be transported to destination di, while the total capacity that ti can hold is Ci. Find the optimal way of executing this task.

The expressions that we want to minimize are:

where oij is the number of times transport means tj has been used to reach destination di for all i. Another constraint we have for the above expression is that:

for all i because the transportation should be able to deliver all the goods successfully to the respective destinations.

To reduce lead time, the best option is to do all of it simultaneously, because

definitely there will be enough trucks for transportation, and there is no use waiting

for the truck to go and come and send them for delivery again, since the cost is the

same, but the time is getting wasted. So the best solution for lead time reduction is

to simultaneously deliver the goods to all dealers.

Fragmentation & Consolidation

In the 1960s, industrialists realized the need to segregate the delivery of a product into different dimensions, since purely transporting goods from one place to another would turn out to be a total waste if we did not take care of the more important aspects, such as inventory management. At that point, industrialists charted out the tasks that have to be carried out during delivering the product to the end consumers:

- Demand Forecasting

- Sourcing

- Materials Handling

- Inventory Management

- Job Scheduling

- Production Planning

- Order Processing

The reason why this era was known as the fragmentation era was because each of

these tasks discussed above were considered as separate tasks. Separate teams were

set out for each task, and thus there was a lot of miscommunication between them.

For example, the demand forecasting team has to report to the sourcing team who

will report to the inventory management team and etc, and if some information is

miscommunicated, it could lead to chaos. Moreover, teams would have no concrete

idea on what they are supposed to do, as this separation between teams is ghastly

and does not serve the sole purpose of integrated work. Now due to this, in the 1980s,

industrialists realized that this separation is highly pointless and since there is too

much tight coupling and cohesion between these tasks, industrialists merged all these

tasks into one sole task: Optimized Logistics. Another important philosophy that

was embraced by industrialists was that supply chain work inside the operations of

the firm as well, so every process in the operations of a firm is part of the supply

chain. Every internal team member with respect to the organization was considered

a node in the network. This was one of the remarkable discerns that was made by

industrialists and committees at that point.

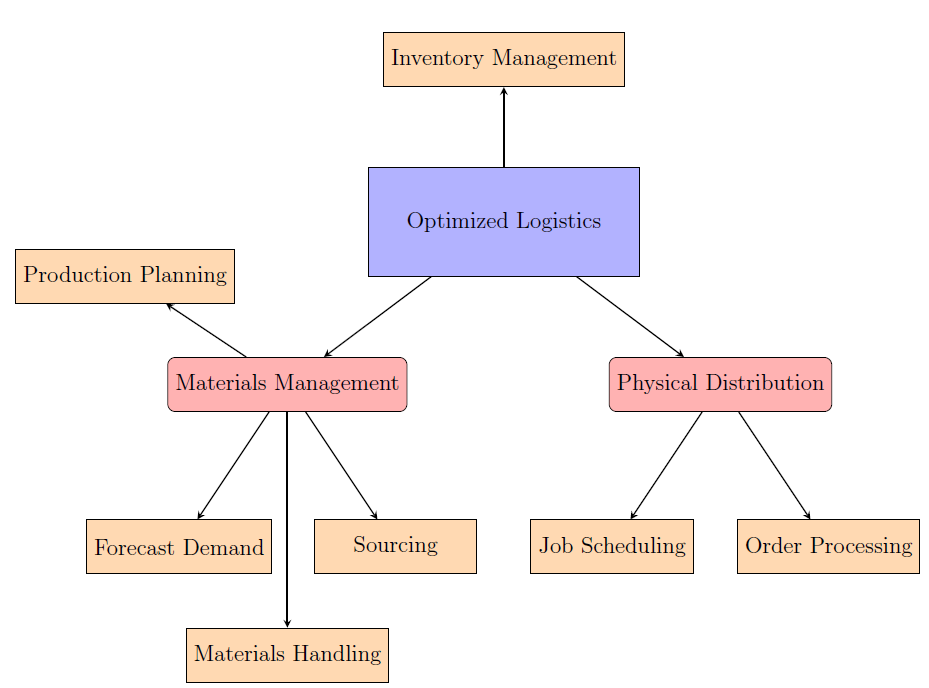

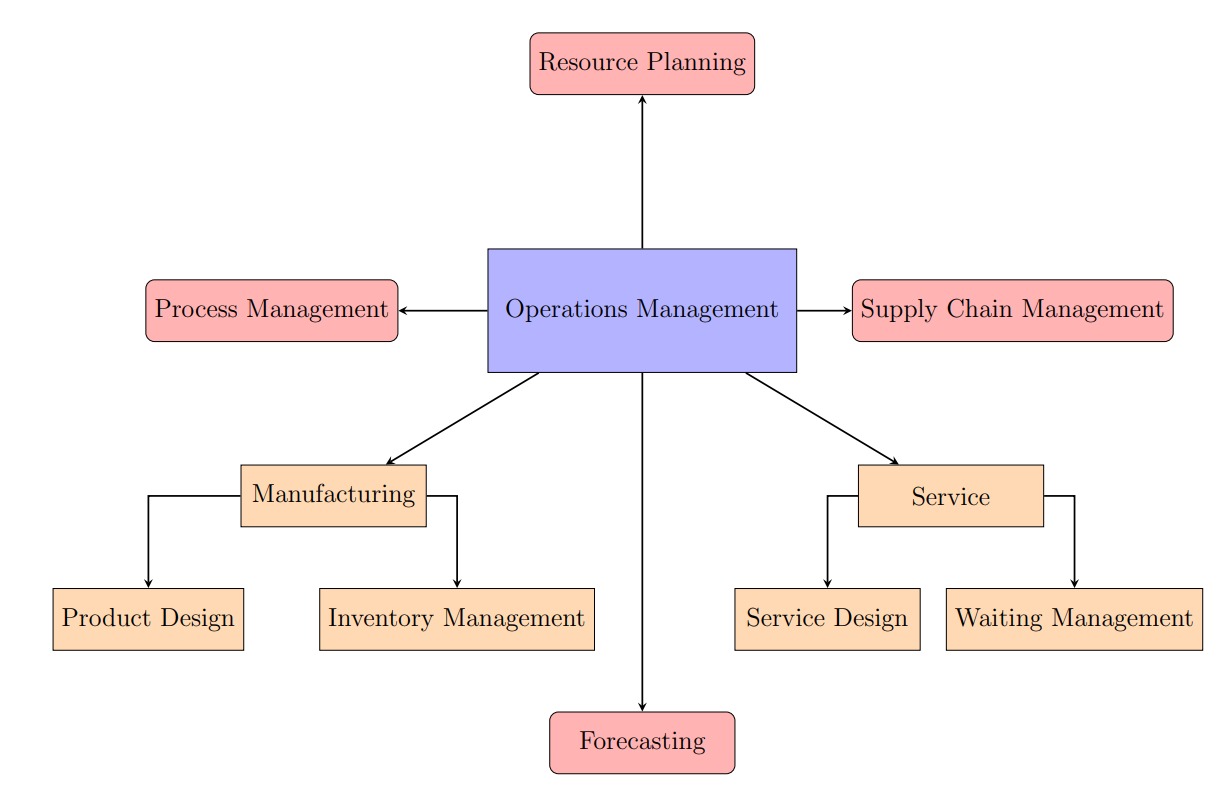

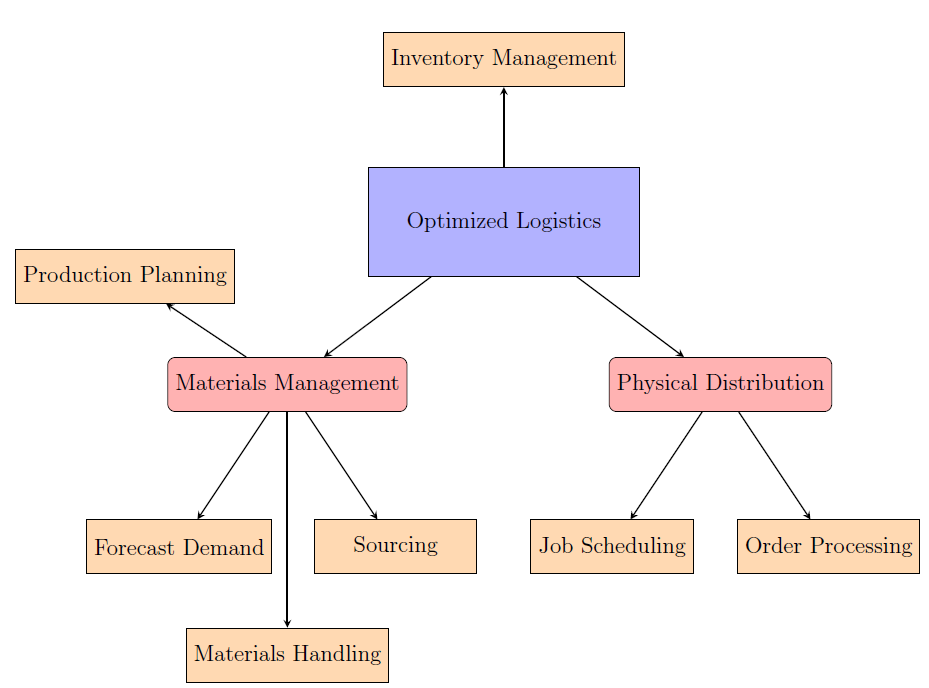

At this point, all industries now turned their attention to the so-called Optimized Logistics

Management. Below is a graphic view of the components involved in optimized

logistics management:

As you can see in the figure, four of the seven components involved in optimized

logistics are inside the Materials Management section and two of them are in

the Physical Distribution section. With respect to a firm, materials management

refers to cultivating and maintaining materials, while physical distribution refers to

the distribution and flow part of the supply chain. The reason why Oliver made this

distribution at that time was because he realized that to consider the entire supply

chain holistically as one functional unit, it was necessary to categorize these fragments

subtly into categories depending on the major functionality of the supply chain.

Another important decision of his was to separate Inventory Management from

both materials management and physical distribution. Since inventory management

tries to fill the gap between them, it is partially materials management and partially

physical distribution.

Now, to scent the beauty of this dissociation, we will first talk about materials

management and physical distribution, and then connect these through inventory

management. In each of materials management and physical distribution, we shall

talk about why exactly these two major components contain explicitly, the minor

components.

Materials Management

When it comes to materials management, as the definition states, this is related to

manipulation of materials. If we want to manipulate materials, we need to know the

supply that is required. What motivates the decision that finalizes our bill of materials?

The demand of course. This is exactly why we need to forecast demand. Now, when

you know the demand, you need to plan the requirements and the processes, which is

why we have production planning included. What do you do after you have a plan?

We need to source the materials of course, which is why we have sourcing. Finally,

when the materials are sourced, we have to handle those materials, where handling is

an activity that is considered to choose itself from transformation or transportation.

Now that you know what exactly persists in the materials management framework,

let's dig in deeper into the four components of this framework.

Forecast Demand

When we say ”forecast”, which literally means ”predicting the future”, we expect

objects, heavily derived from the mathematical framework to be instantiated. What

kinds of objects? To know about that, keep reading, and that will be covered in the

upcoming sections.

Forecasting demand as a whole is a very complex concept. But to get a sense

of how to forecast, we generally try to derive from the marketing 2.0 framework,

which corresponded to Gen X, concepts that pertained to the creation of value. In

short terms, forecasting demand was a process that undergoes a subtle ”give and

take” policy.

Since most firms considered supply chain management as a separate functional unit, and not something that integrates with other departments, demand forecasting

was not very successful, and planned attacks seldom existed.

So how exactly is demand being forecasted? To know that, keep following me to the next sections.

Production Planning

When we have some idea on the demand, and the final features of the product are

finalized, we have to plan the requirements and the entire production process. This

is a highly generic statement, when we enter the specifics for each industry, we find

different techniques in each of them.

What we will do instead is try to write out some generic outlines as to how we

can plan our production.

Firstly, in any production plan, there are three components:

- People

- Processes

- Common Components

First, when it comes to people, there are some generic management techniques one

needs to know. Firstly, and most importantly, the transfer of artifacts between people

has to be minimized. We don't want someone to look up to someone else's work.

Next, we need to keep track of people's work. Finally, as said by Mark Christopher,

supply chain exist inside a firm as well, we must try to impart some basic supply

chain management principle while transferring artifacts from person to person.

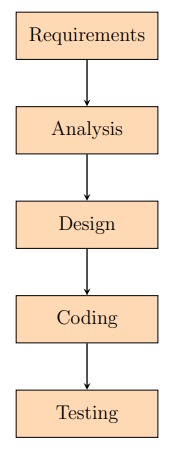

Second, processes are something that co-exist within each other and the entire

firm. Now, we try to understand in quite a bit of detail, about process management.

Process management is the art of managing processes in ways that meet demand

after successful forecasting of it. There are three types of processes:

- Senior Processes

- Core Processes

- Supportive Processes

Senior processes are processes that govern and control the core processes and strategies

in ways that keep the deviations in statistical business figures under control.

Core processes are the processes that actually convert inputs into valuable outputs.

These processes can be considered as transformation processes.

Supportive processes are processes that assist the core processes, for example, parallel

sub-processes in the chain of core processes.

The goal of the firm should be managing these three processes in ways that meet

profitability and consequently demand. Senior processes should be very efficient and

quick in reaction. Most senior processes abide decentralized management rules.

When designing core processes, there are three questions to be addressed.

- What do we need?

- Why do we need?

- Who do we need?

The first question is in regard with the aspect that is lagging in the firm. For example,

a car manufacturer lags windshields. The second question is in regard with the reason

of that need. In the windshields situation, windshields are mandatory, because if it

rains then drivers won't be able to see clearly. Finally, the third question is in regard

with the set of ground workers who shall execute the task.

When these questions are addressed, we ask this set of questions again. Which

means, in order to successfully attach the windshield in the car, the questions are

asked once more, what do we need, why do we need and who do we need. These

questions are asked step by step until the entire design is very clear.

Designing requires high level of organization, after each set of questions, the needs should be arranged in order, so when we reach the final needs, where no more questions

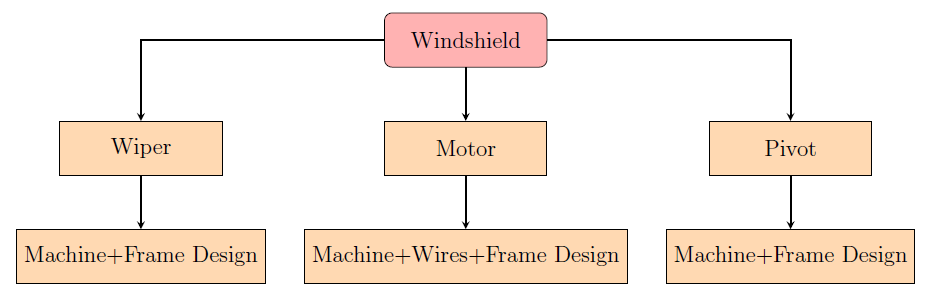

can be asked, the entire process design is in order. Here is the example of the

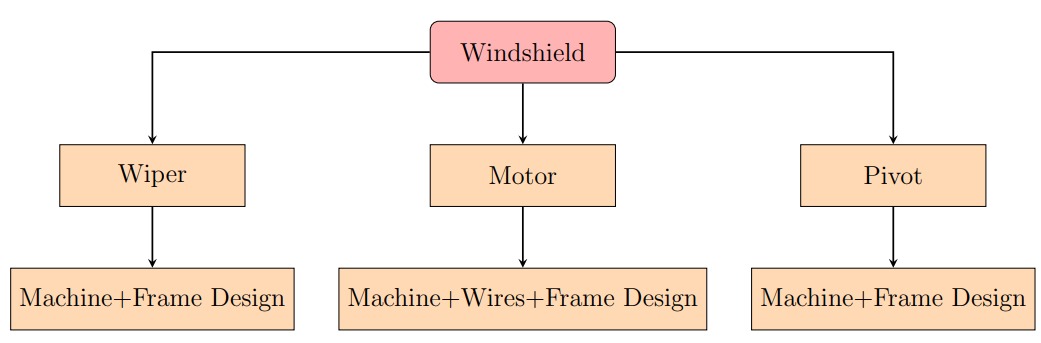

"what do we need" for a car windshield:

And so the root needs are reached and organized. Another important fact that we

must consider is that, when we put '+' between two non-machinery attributes, it

means there is another machine that assembles them together. So for the motor leaf,

between wires and frame design, there is a second machine that puts them together.

Finally, all the three nodes, wiper, motor and pivot are all assembled together to

make a windshield.

This means, under a node, if there are n non-machinery attributes, there should be at

least one more machine that combines those child-nodes together to make the parent

node successful.

Drawing the design in the form of a flow chart always helps, because it gives a

very good visual. Designing core processes are not the job of one man or one group.

It requires the whole organization to work towards it.

I have also discussed the notion of supportive processes above, the process that

is sub-designed under the core process that assembles more than one non-machinery

attribute is called as a supportive process. Supportive processes can also be called as

parallel dependent processes. One example of supportive processes is the HR training

process that undergoes in any firm.

When we do this, we get a very good idea as to what exactly we want and how we are going to achieve it, and therefore, it is now time to move ahead to the next step

which we must take: Sourcing.

Sourcing

Sourcing with respect to a firm is about sourcing external materials into the organization,

i.e. purchasing materials. This may sound fairly easy, but as far as Optimized

Logistics is concerned, it is not. Now, we present the sourcing problem.

Assume that you want to purchase M materials of the same type, and you have

suppliers S1, . . . , Sn, and suppler Si quotes cost ci per material. On order of xi,j or

more materials from supplier Si, for 1 ≤ i ≤ n and 1 ≤ j ≤ f(i), where f is the

function that sends supplier indices to the amount of schemes, you get a discount

of di,j percentage. Each supplier Si can supply at most Ti materials. What is the

optimal way we can place our orders to these suppliers?

We want to optimize:

where 1yi is di,j , where j is the largest positive integer so that yi > xi,j . We also have

the constraints:

as well as

yi ≤ Ti∀ 1 ≤ i ≤ n

This problem is quite complicated, as we have indicator variables appearing in the

picture. In the area of linear programming and regression, there is a technique that

deals with indicator variables called sparse regression and convexifying non-linear

programming problems. What we do here is basically use mathematical algorithms

to simplify the use of indicator variables, which we will exclude from this paper, as it

is already a huge research topic.

Once we source the materials, we move ahead to the next and the final component: Materials Handling.

Materials Handling

Materials handling can be considered as a "controlled" execution of production planning.

The fact is that things may not go as expected, and that gap is what we

call delta. To control that delta, we are calling materials handling as a controlled

execution of our plan. Here is where an extension of process management comes into

picture: Process Control.

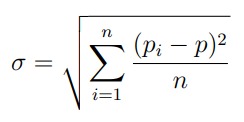

The efficiency and effectivity of the process should be measurable, in which sense,

there should be benchmarks which can point the level of process quality. The controlling

of these parameters is called process control.

A vague picture of the measure in quality of processes can easily be figured out

while proofreading the output. But the major challenge is to figure out the exact

process and aspect that is getting out of control. In order to measure that, we have

some techniques

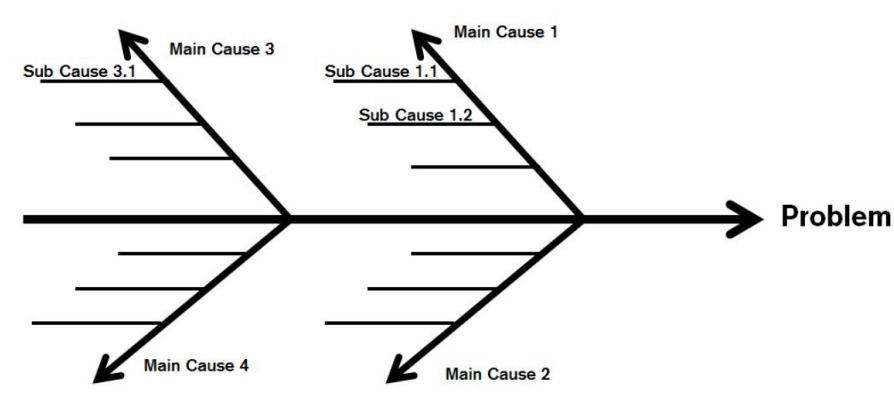

- Control Charts

- 5 Whys

- Cause and Effect Diagram

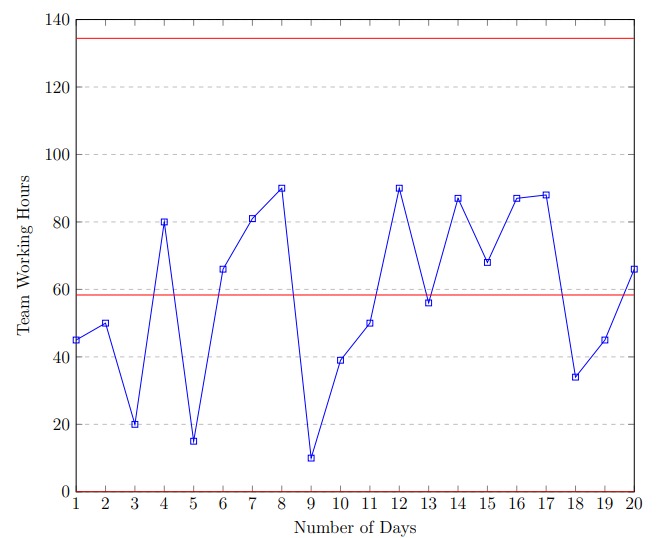

Control charts are a pictorial representation of variations in the process. Control

charts contain two limit lines, the UCL and LCL. If an attribute exceeds the control

limits, then that attribute requires serious care, else we are good to go.

5 Whys analysis is a singular approach to to understanding the root cause of the

problem by repeatedly asking 5 Whys. The answer you get in the end is the root cause.

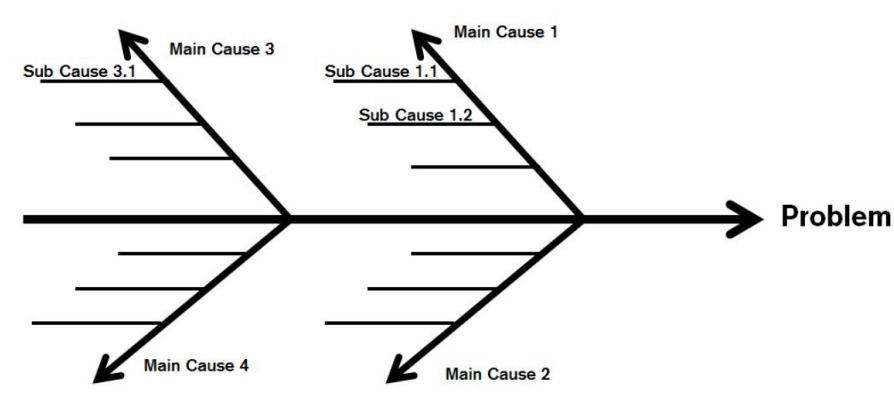

Cause and Effect diagram is a multilingual approach to finding out all the root

causes of an effect. Each and every aspect is discussed in detail in this analysis, unlike

the 5 Whys which only goes to the root causes and does not understand the entire

context behind it.

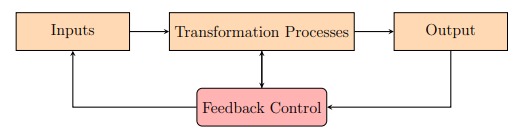

In contrast, process controls are a form of feedback and feedforward controllers,

feedback controllers being taking action after the effect and feedforward controllers

being taking action before the effect.

Investing on feedforward controllers is a lot more beneficial than investing on feedback

controllers, because the effect doesn't even happen!

Physical Distribution

Physical distribution is focused towards the other half of the supply chain. There are

two primary components in this framework, job scheduling and order processing.

I will elaborate more on what we mean by "Order". An order to a node is a

situation that commands that node to execute a certain action, in this context,

transmitting. So, an order does not necessarily have to be placed by a consumer,

an order can be placed by any other node (including that node itself). Customer

servicing is also an order.

Now, the first thing that happens in physical distribution is the wait for an order

by any node. Once we get that order, we process that order and schedule

distribution jobs amongst other nodes, for example, transport facilities. These are

the two major components in the physical distribution framework, and now we shall

dig deeper into them.

Order Processing

We must first note that the flow of information through the supply chain is as important

as that of the materials.

When an order is placed, it is important to inform node that placed the order

about the status of the delivery. Again, delivery here is a very broad term that tries

to represent the expected response to an order. So, when a product arrived, it is a

delivery, when a technician comes to service a repaired fridge, that is a delivery as well.

When an order has been placed, we need to first validate whether the order can be

delivered or not. If not, we have to pass back information that the order cannot be

completed.

Next, if the order can be processed, it is important to state the time taken for the order to be processed.

Once the order is processed, we have to inform the receiving node that the order

has been processed.

These are the fundamental concepts of order processing.

Job Scheduling

Job scheduling in the context of optimized logistics is executing a medley of tasks in

an optimal amount of time. Therefore, we present the generalized assignment problem:

Assume that we have to complete tasks t1, . . . , tn and we have resources r1, . . . , rm.

The cost to assign task ti to resource rj is ci,j for all 1 ≤ i ≤ n and 1 ≤ j ≤ m. Find

the most optimal way to execute these tasks.

We say that xi,j = 1 if task ti is done by resource rj and 0 otherwise. Then,

we want to optimize:

Which can, yet again be solved using linear programming techniques.

Inventory Management

As we said earlier, inventory management fills the gap between materials management

and physical distribution, but why? First, let's understand the concept of an inventory.

The most common mistake that is made by people, is that people consider an

inventory as a godown. This is what firms thought in the 1950s, i.e. the misconception

era, but an inventory is a lot more than that.

Formally, an inventory is the element that connects two disjoint processes in the

supply chain. In the entire supply chain, we have multiple disjoint chains, a product

cannot be engineered in one go from the raw materials. When materials go through

a process and transform into artifacts that concludes a chain, we need to store those

artifacts in an inventory, and then those artifacts are pushed in as materials in another chain. The creation of artifacts falls under the materials management framework,

while the distribution of artifacts from one chain to another falls under the physical

distribution framework. This is exactly why we claimed that inventory management

bridges the gap between the two frameworks.

In the optimized logistics framework, the primary objectives that we want to attain

through inventory management are:

- Easier locating of goods

- Minimizing physical risk and motion waste

- Coupling disjoint processes

- Controlling inflow and outflow of goods

We are now ready to formally define inventory management:

Definition of InventoryManagement

Inventory management is the art of optimizing

inventory costs, minimizing transportation cost and classifying inventory stock.

Minimizing transportation costs has been discussed in the earlier chapter, where we

presented the generic solution to the generic transportation problem, so we will be

talking more about optimizing inventory costs and classifying inventory stock.

Optimizing inventory costs

Inventory cost consists of three different costs:

- Ordering cost - cost that is payed for ordering goods.

- Holding cost - cost that is payed for storing the goods, such as, depreciation,

deflation, taxes, spoilage, etc.

- Shortage cost - cost that is payed when an order is placed by the customer but

there is no stock in inventory.

The firm's key goal must be to minimize these costs. The first and foremost cost that

must be minimized is shortage costs. The other two costs don't make direct impact

of the firm in the market, while shortage costs may deduce customer retention rate.

The second most important cost is the holding cost. Storing too much of inventory is a phase of waste, especially for expire-able products, since they have a deadline

of usage. Most importantly, overloading of inventory causes blockages in the supply

chain, which is dangerous for the firm. The final and the least important cost is the

ordering cost.

Firstly, shortage cost should not exceed a penny. Secondly, holding cost must

be minimized. That means, we can minimize both the shortage cost and holding cost

by purchasing goods that are equal to the customer demands. This way, maximal

goods shall take part in the supply chain, thus minimizing blockages. As professor

showed us in the simulation exercise, minimal inventory is better than inventory

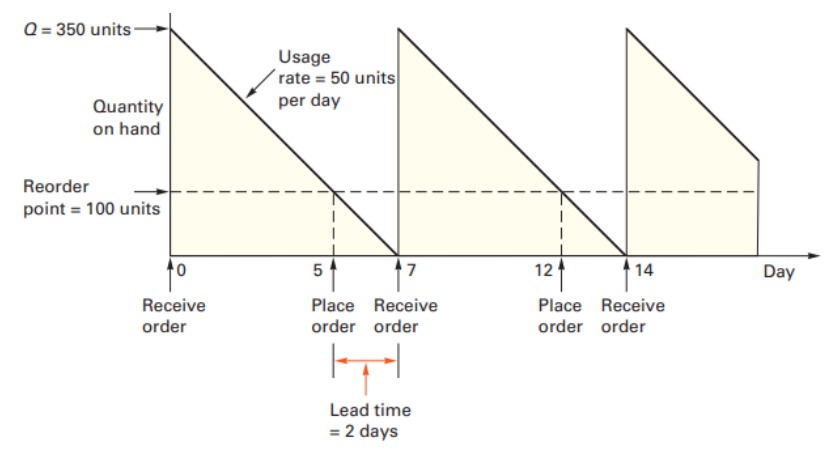

overload. We can thus mathematically conclude that the reordering point would be

when

Stock at point = Forecasted demand x Receiving time

and the reordering quantity would be

Reordering quantity = (Receiving time + gap) x Forecasted Demand + U

Here, receiving time is the time taken for the goods to enter the inventory. U here is

the extra goods required in case there are any variations in the forecasting (buffer

stock), and we are doing this because, shortage cost must equal zero. Finally, the gap

is the number of days in which the reordering point appears. It is best that gap is

minimized, because variations in demand shall cause blockages which can be painful.

We have seen how industrialists worked with optimized logistics. Now in the next

chapter, we will see how industrialists completely changed their thought process.

Classifying Inventory Stock

The most important differentiation between an

inventory and a godown is that, an inventory classifies its stock and maintains a

proper catalogue of it's items. How exactly does the inventory classify its stock?

First of all, inventory stock must be classified based on the demand of products.

There are different analytical techniques to classify stock, such as ABC Analysis

and Movement Analysis which were discussed in my previous article, MBO in

Investments. When we classify inventory stock appropriately, it becomes easier to

locate items, and most importantly, keep the interfaces for delivering high-in demand

products easier to access.

To conclude with, inventory management is one of the most important components

in optimized logistics that minimizes blockages, or bullwhips in the supply

chain.

Integration

Up till now, we saw how the world changed its views and perceptions on supply chain

management from the second world war, till the 1980s, where industrialists considered

supply chain management as a disparate functional unit. During this period, a

double-dip recession hit the world, which caused severe inflation and unemployment.

Why is it that this event occurred? What caused this recession? To understand that,

let's first understand the situation that we can imply from the discussions above. As

you might have noticed, firms at that point of time spend money on the delivery

of a product without a foolproof plan. Why do we claim that they did not have a

foolproof plan? Well that's simply because the forecasting of demand cannot be done

without deriving concepts from marketing!

Now let us understand what causes a double-dip recession. But before that, what is a

double-dip recession? Well, a double-dip recession is a recession followed by another

fresh recession before the old recession occurred.

What causes the original recession then? Generally recession is caused when inflation

increases, and inflation is caused when too many loans are pending to be

fulfilled. The double-dip recession is caused when there is an imbalance between

demand and supply, which would cause high levels of unemployment, or wages would

be incredibly high.

Getting back to the story, at this point of time, most firms did not forecast demand,

and to execute the optimized logistics, they took loans from banks. But in

the end, firms went in losses, since the demand wasn't forecasted, and loans were

pending to be fulfilled. When most firms are facing losses, there would be one firm

where a lot of traffic hits, and that is where the bullwhip occurs in the supply chain,

unlike other firms where demand was less and supply was high, here, it would be the

opposite, demand is high, while supplies are less. This made the few firms that hit a

lot of traffic to increase prices in products, due to which inflation occurred, and this

combination caused the double-dip recession.

During this period in 1982, a man and his friend Tim Laser coined a term called

Integrated Inventory Management, and the main idea behind that is to integrate

optimized logistics with the other functional departments such as marketing and

finance.

During an interview with electronics giant Philips, that man was triggered by a

customer service manager Van T 'Hoff, where that man couldn't explain briefly about

his idea of I2M. Due to this, he sub-consciously named his idea in that interview as...

"Total supply chain Management". As you might have already guessed, that man is

none other than Keith Oliver.

From that point onward, in the near 1990s, firms started to integrate supply chain

management not only with the operations team, but also with teams such as marketing,

finance and HR. This re-shaped the way firms forecasted demand, and now you

shall see the second part of demand forecasting:

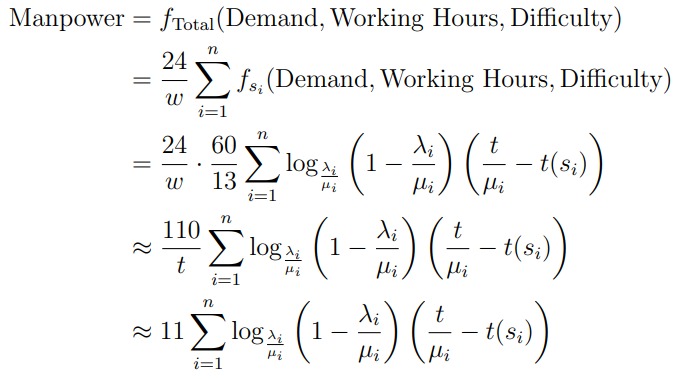

Forecasting is a concept that relies on three things:

- Data

- Mathematics

- Approximations

Which can be mathematically represented as

Forecasting = f(Data, Mathematics, Approximations)

Forecasting can be successful if and only if, the customer inputs are converted into

an output, which means, the consumer behaviour and responses should be converted

into a superior product with high quality measures.

The most important aspect of all aspects in forecasting is the observational data

that the firm has, in which sense, the data available about consumers on other

firms. A combination of observational data and customer responses from appropriate

questionnaires (which is carried out by the marketing team) shall reveal the problem

that consumers are facing, and a vague figure of the demand that shall arise, for

example high, medial and low.

To come out with more accurate figures, the firm must measure customer responses

by the most challenging problem they are facing, for example, scrolling down to the

bottom of a page on button phones. Another important fact that must be taken

into consideration is that when a consumer invests his time into answering the firm's questionnaire, he has some genuine interest towards the firm.

Now the excitement and enthusiasm of the questionnaires responses shall be categorized

into three:

How do we measure excitement and enthusiasm? Well, excitement and enthusiasm

are inversely proportional to the current comfort levels that the target market has

with respect to the domain of our firm, so we can categorize the excitement and

enthusiasm by reverse-engineering the responses given in those questionnaires.

Assume that h are highly enthusiastic responses, m are medially enthusiastic responses

and l have a low level of enthusiasm. If the marketing and quality combination is

done very well, then those h customers shall be the first to purchase the product

at it's release. The next question that arises is, how many of the m + l customers

shall purchase the product? In order to answer that, more questionnaires should be

released to samples asking them about their expressions about products of other firms

when those firms sent them a set of questionnaires regarding their product. Sample

size shall be selected through concepts in sampling theory which shall not be discussed

here. When a set of a customers react to medial and b of those purchased the product,

then b/a of the medial customers bought the product, while in the low category, d/c

bought the product. Circulating such questionnaires to samples about different firms

shall yield the percentage of medial and low customers that actually bought the

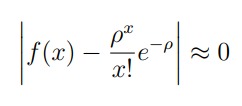

product. Taking the poisson distribution shall tell the firm the two percentage rates

ɑ and β of medial and low customers respectively who bought the product after it's

release. So, the demand estimate would be

and thus the demand is forecasted.

Note that this is a very simple model presented above, complicated models require

gritty estimates which shall not be discussed in this article. From the observations

above, we see how we instantiated objects from the marketing 2.0 framework, and how tight, marketing and supply chain management is.

This decision by firms is one of the most remarkable decisions, where optimized

logistics are aligned to various strategies that are present in the strategic growth

framework. This was the turning point in the evolution of supply chain management,

and of course, the most historical age since the past fifty years of evolving, and

evolutions to come.

Automation

While supply chain management did evolve well, in the early 2010s, we entered the

digital era. At this point of time, firms really needed to move from the traditional

way of supply chain management to incorporating technologies in supply chain management.

The first technology that was incorporated in supply chain was the IOIS, i.e. Interorganizational

information systems. The IOIS tried to come close to the modern day

technologies such as AI and IoT, but unfortunately, it failed, due to lower granularity

levels. The IOIS had five levels of participation:

- Remote I/O node - This creates point-to-point interactions between firms and

a sensor on the local I/O enables actuators to begin the processing.

- Application processing node - This takes into consideration the details given by

consecutive firms for packaging and delivery, and executes the task as needed.

- Multi-participant exchange node - This is a degree addition of the previous

node. This node enables multi-application processing, from one point to different

low-level points.

- Network control node - This node automates maintenance of inventory levels,

figures out potential errors in the network and fixes them, so it is basically a

feedback controller.

- Integrating network node - This node allows other firms to integrate themselves

in the supply chain, yet keeps the entire processes above stable and secure.

The reason why it was less granular was because it couldn't manipulate information

well. Now, we shall move on to the latest technologies, and how the escalate the

quality of supply chain management. The two technologies that we will be talking

about are:

AI & IoT

The world is changing, earlier we used to have people doing physical jobs, such as

delivery boys, drivers, cleaners, carpenters, technicians, and now we are going to have

drones, self-driving cars, robots that clean entire houses and robots that can literally

build themselves! The world ahead of us is going to be conquered by robots, robots

shall replace humans, only innovators shall survive and the rest would be leading a

miserable life! Drivers, cleaners, delivery boys, all go out on strikes, because if you

don't, then you may not survive.

This is a common misconception that the entire world has on AI. Many even go to

the extent of demoting AI & IoT and many went out for strikes. The fact that the

common man is not realizing is that AI & IoT are just regular devices and have

boundaries. As Grady Booch explained in his ted-talk, "To create a machine that

can replace human, it would require way too much of training". So what exactly are

AI & IoT, and why can't they replace humans even at the most mundane job ever?

To understand that, let's first grind some fundamentals out of AI & IoT.

AI when expanded stands for "Artificial Intelligence". Before understanding what

this term means, let us first understand what intelligence means.

Intelligence contains two components

- Learning Ability

- Analytical Ability

Learning ability is about the ability to process information, mostly inputs and outputs.

As mam cited an example, you have cats and dogs. When you feed yourself those

images, and the labels, you realise that "if it looks like this, then it is a cat, otherwise

it is a dog". Throughout our whole life, we have been learning. How else does a kid

speak his mother tongue without any training? The kid hears the input, and sees the

output, and then realises what his parents are talking about. When his mom says:

"Darwaja Khol", which stands for "Open the Door" in Hindi, the kid sees, that when

the Hindi word is uttered, that particular action has to take place, so the next time

his mom says the same thing, he will go and open the door.

Analytical ability is the ability to compare two different data sets and create an

inference. When experienced HRs validate interviewees within seconds, it is not

because they have magic inside of them, but they have seen multiple candidates. Here,

they notice two different data sets, one, the set of answers to questions, and two, their

performance. What they are doing here, is they are feeding themselves with data,

which is then processed into experience, and next time when a candidate utters similar

answers to a candidate that did not perform well, the HR wouldn't hire them at all.

Artificial intelligence is trying to push these abilities inside that of a machine. When

we do so, this might allow machines to give valuable "predictions" using big data.

Now, what is IoT? Well, IoT, which is expanded as internet of things, is basically

a data adaptor that converts a physical scenario, such as the tap of a button,

into an expressible event inside the cloud.

Generally, when we talk about modern day technology, we cant seem to separate AI

and IoT, and instead, we talk about the Interplay between AI & IoT. The IoT collects

information and passes it on to the AI, which then takes a decision and the IoT

expresses that information back, physically. For example, consider the case of looking

for firearms. The IoT sensor that takes an X-ray of the luggage sends the X-Ray-ed

image to the cloud, where the AI exists, and the AI validates the information. If there

is a firearm, the AI reports back to the IoT, which then expresses the result: an alarm.

I will now answer the hot question: why can't AI& IoT replace humans. You

see, the difference between us humans and machines is that, our brain is boundless.

Humans have no boundaries, our brains can stretch to extreme limits, unlike machines,

which have a boundary.

In every class of situations, there exists a layer of situations, which we call ”Noise”.

These noisy situations are known as unexpected situations. When an AI encounters

unexpected situations, its analytical results could create ruckus. How? To understand

that, let's take the case of self-driving cars.

Assume that a driver is going across a street, and he encounters a man in the

middle of the road, laying down, injured. Obviously, that man will stop the car and

go help that man.

When it comes to self-driving cars, the IoT sensor of the self-driving car would

send the information of something ahead in the road. The AI device might not

have been trained to identify injured people that it would stop, and so instead, it

considers the injured man as a speed breaker. The moment this decision is taken by

the self-driving car, the car would go over the injured man. This is an example of

why AI & IoT cannot replace humans.

Another famous example, is the worlds first ever robot-staffed hotel. The guests of

this hotel had a nightmare of a stay, since the robots misinterpreted the snoring of a

man as a call for room service and kept belling the guests all night.

The real question now is, how in the world then, do AI & IoT benefit us? The

true benefit arises only when these technologies are used only where they are supposed

to be used. If you give a carpenter a driller who uses it as a hammer, he would

return with holes in walls, and of course, several smashed fingers.

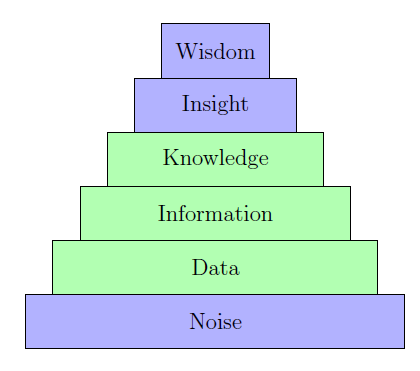

This is where the human-machine pyramid comes in. The human-machine pyramid

gives a clear distinction as to what the roles of a machine are, and what the roles

of a human are. Here is the pyramid below. The blue sections are tasks that would

be carried out by a human, and the green sections are those which should be carried

out by machines.

Let us describe these six roles in detail:

Wisdom

Wisdom is something that is purely attainable only by a human, and

wisdom is about making wise decisions. This stands on top of the pyramid, since this

is the exact reason why we humans are much more intelligent than robots.

Insight

Insights are something that relate to the analytical abilities, the conclusions

we can draw from situations. This is also something that has to be majorly

taken care of by a human.

Knowledge

This is the repository of inputs and outputs that the machine stores,

which it will use to take a decision in future.

Information

Information in this context is about converting the data that comes

in different forms into something expressible.

Data

Data is just the set of inputs and outputs of a given situation in an unorganized

way.

Noise

As described earlier, noise is an unexpected situation, which must be left for

a human to handle.

As you may notice, we have made a clear distinction between the roles of a machine

and the roles of a human. The reason why data, information and knowledge is given

to the machine, is because machines are much better than humans at processing

data. They can organize disorganized information way better than humans, and can

easily deal with non-noisy situations. When we make use of machines from this angle,

experienced is escalated. But how can we make use of AI precisely? Well, we can

let AI handle very basic scenarios and use it as an advisor and not an actuator to

slightly complicated scenarios which would then be validated by a human.

But how does all of this relate to supply chain? You see, AI & IoT primarily

extend the original idea of IOIS, except that they provide better granularity. The

usage of IoT in supply chain is primarily arched towards inventory management. IoT

can help transfer data into a cloud which can then process and store data easily.

We wouldn't need a supervisor that notes every single transaction, but instead, we

would need a supervisor that "supervises" the information being processed. Using

IoT, we can find the item that is the most moving, and when this information is fed

into the cloud, the AI makes a recommendation to classify inventory stock differently.

That recommendation is then validated by an actual human, and then implemented

accordingly.

AI also helps in the forecast of demand. The marketing team does an additional

exercise of sending questionnaires related to the products of other related firms, the

AI then takes the data set of responses and the actual output (the results) that

happened, and tries to create a correlation between those data sets. Once we do that,

we feed the AI with the responses of the current market survey, through which the AI

makes a prediction of the amount of demand. How does it make this prediction? We

use tools from mathematics such as simple regression, polynomial regression, sparse

regression and so on.

We now move on to concepts in Blockchain and how it is being used in supply

chain.

Blockchain

Centralization is something that always co-exists, there is one guy that takes all

the decisions. Blockchain aims to get rid of that central entity, the decisions are

made by participating entities. The primary idea of a blockchain is to decentralize all

centralized decisions which we, the public have no idea of. The blockchain idea was

first implemented in currencies, the end product being bitcoin, which was published in

2008 by Satoshi Nakomoto. The main idea of bitcoin was to make secure transactions,

transactions that were immutable, and validated by a consensus.

To express the concept of blockchain, we will align the main ideas of blockchain with

bitcoin.

Firstly, there are three aspects when it comes to decentralized electronic peer-to-peer

cash systems:

- Transaction Validation

- Immutability

- Security

In addition to these, bitcoin provides us with an extra functionality which we call a

smart contract, that would create a blueprint for the transaction to be executed. A

smart contract plays an important role within blockchain. We shall understand how

bitcoin attained these in detail.

Immutability

Immutability is something that is necessary in our day to day life, we need to make

sure that information is legit. If the set of transactions that have been committed

are tamper proof, then the whole ledger is trustworthy and note that each and every

node has the latest copy of the ledger.

Satoshi presented a neat solution to execute immutability, that is, by introducing

the notion of a block and the notion of a chain. A block is a combination of

two objects, a header and a body. The body contains all the validated transactions

under a time-limit, while the header contains metadata of the block, as in, it contains

the hash value of itself, the hash value of the previous block, the time-stamp and

the Merkle-root hash. Take everything granted for now, we will explain in detail

how exactly they work, but just notice a property of the block: It contains the hash

value of itself and the hash value of the previous block. How to find this hash value?

That will be explained in the later sections, but as of now, consider hash value as an

unique identification number. By containing the hash value of itself and the previous

block, the two consecutive blocks get "chained". This means, all the transactions can be segregated into blocks with respect to time, and chained together. The entire

ledger is distributed into blocks that are chained in a consecutive manner. The first

block in this chain is known as the genesis block, which is a special block, since it has

no previous block.

How does introducing blocks and chains help us here? Well, if an evil node wants

to change any valid transaction, he must first change the block that contains it, but

changing the block causes dramatic change in the hash value, thus breaking the chain!

And that is a notification to all the nodes in the network that there is some problem,

and the change in transaction shall be rejected by all.

Transaction Validation

Transaction validation is primarily about checking whether a transaction is a double

spend or not. What is double spending? Double spending occurs when two amounts

of the same value are transacted, but only one amount is deducted. This problem

can be solved by introducing the notion of a timestamp server. If the latest digital

signature and the timestamp (of when the transaction occurred) are the same for

two coins, the miner shall reject the transaction. While if one miner accepts one

transaction and another accepts the other, then by the longest chain algorithm, only

one of those two blocks are going to be valid, thus rejecting the double-spend.

Since blockchain is decentralized, there needs to be some form of democracy in

this transaction validation, how does that happen? This is exactly where the concept

of consensus comes into picture.

There are two types of consensus, qualitative consensus and quantitative consensus.

- Quantitative Consensus - Number of people deciding upon a single transaction's

validity.

- Qualitative Consensus - Systems deciding one person who decides a number of

transaction's validity.

Qualitative consensus is better than quantitative consensus in many ways. One reason

is scalability, but the major reason is, evil nodes can create thousands of alts, and

the evil side will win the consensus, so quantitative is completely eradicated.

How does the qualitative consensus work? All the nodes in the network will be

given a certain task, and the winner of the task gets to validate the transactions.

What exactly is this task? Here is where the hash value of a block comes in. The

task, that will be given to all the nodes is a computationally difficult problem, which

is known as proof of work. The problem is to find a hash value less than or equal

to the target hash. This can be done by taking the previous completed hash and

adding a nonce to it and re-hashing the result. A nonce is an integer that is used

only once. The difficulty here is to find the nonce value that gives us a valid hash

that is at most a target hash. All the nodes work on finding the nonce value, and

whomsoever finds the proper nonce value wins. What if two people found the nonce

value in the same time? In that case, both of them get to validate the block, and

there are two "brothers" in the chain.

This causes serious problems. To solve this, we adopt the ”longest chain” algorithm.

What this does is, it takes the longest chain as the current state of the ledger,

because nodes can choose to work on either one of the blocks, and the chain that's

the shortest among both brothers would be simply broken.

How does all this guarantee that the ledger is valid? That's simply because, the

plausibility of assuming that the winner of the proof of work is honest is equal to

the plausibility of assuming that the individual who has a computer with maximal

computing power is honest. And that's pretty true, because authorized entities only

own quantum computers. The longest chain algorithm also shows that the longest

chain between brothers is more valid, why else will honest nodes invest their time

onto it?

Even though what we said above seems intuitively good enough, to convert it into

code, it requires a lot more details. So, let us understand how hash functions work.

A hash function is a 1-way trapdoor function, which means, it's easy to go from the

input to the output, but very difficult the other way around. Another important

property of the hash function is that, any minor change in the input causes extreme

changes in the output, in which sense, there is no pattern in the hash inputs and

outputs. Another interesting fact of the hash functions is that, their output string

length is precisely 256 bits, no matter how small or large the input is.

A question that arises is, since the length of the string is fixed, there are only

finitely many possibilities, precisely 2256, so what if, between some two inputs, a

collision happens? That is,

H(X) = H(Y ),X ≠ Y

The best possible thing we can do, is to reduce the collisions. A hash function is

more collision resistant when the algorithm behind it is very good. The hash function

that is used in blockchain is called SHA256, that is, Secure Hashing Algorithm 256,

and has been designed through the Merkle-Damgard construction. Let us understand

this a little bit:

We begin by padding bits to a multiple of 256, which means, if the string length is a,

then we pad -a (mod 256) more bits to the original string, and the additional b bits

that we're concatenating, the first bit is 1 and all the others are zeroes. Assume that

the resulting string has string length 256n, where n is a positive integer.

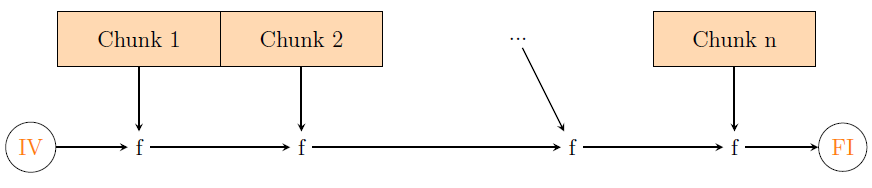

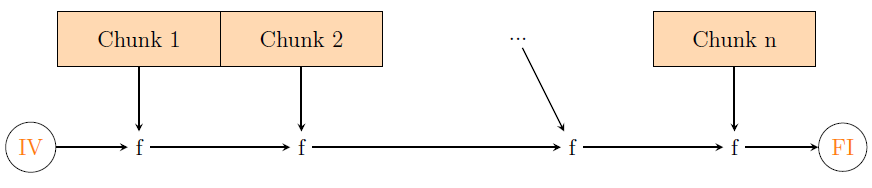

Divide the bits into n chunks, each containing 256 bits. Initialize a value, IV, which

is 512 bit and choose a compressor function f, such that when two inputs are entered,

and one of them is 256 bit, the output is 256 bits too. This can be done through

logical, bitwise left and right operators. Apply f on IV and the first chunk, and you

get a result. Apply f again on that result and the second chunk to get another result.

Apply f yet again, on the final result and the third chunk and keep iterating this

process until you reach the final chunk. Apply f on the final chunk and the result

you got after doing this process n - 1 times to get the hash output FI. The figure

above illustrates what we are saying.

Now, the question is, what is the basis of validation? We told that it's respect

to time, but how exactly? First of all, the process of finding a valid hash for the

block is known as mining, and the set of people who work on mining are known as

miners. On average, a block is mined in 10 minutes, and within those 10 minutes, the

transactions that have been committed would be validated, and the valid transactions

would be filled in the body of the block. The next 10 minutes would receive more

transactions, those would be validated too and put in the block, and so on. An

approximate of 2016 transactions are made within these ten minutes.

Security

Transactions between two parties must be uninterrupted, which means no third party

can interfere. To ensure security between two parties, cryptographic algorithms, such

as Diffie-Hellman, RSA and ECC are imparted.

The most common theme of all cryptography algorithms is the Public key, Private key

algorithm. It's more of a ”lock and key” method, but let's follow standards for brevity.

The public key, private key algorithm works as follows:

- Let A,B be the communicating parties and E be the eavesdropper.

- A sends a lock to B, a copy of which is gone to E, since he's eavesdropping.

- B uses the lock A sent and encrypts the message he wants to send, and sends it

publicly.

- A receives the locked message, uses his key and opens it, while E is busy trying

to find out how he's going to unlock the locked message only using the lock.

The strength of the entire algorithm lies on how hard it is to find the key from the

lock, and the crux of the algorithm is to be able to find the lock and the key.

Converting into mathematical terms, let's learn the RSA algorithm. As of now,

we shall be talking in numbers, and not in words.

The RSA algorithm makes use of a very unique fact. That is, when p and q are

sufficiently large primes, multiplying them maybe easy, but knowing that pq is the

product of p and q is very difficult. Now, choose e such that gcd(e, φ(pq)) = 1 and

find the multiplicative inverse d < ϕ(pq) of e modulo φ(pq). Here are the following

steps for RSA:

- A sends B the public key (e, pq).

- B encrypts the message m as me (mod pq), the resulting answer that he gets is

sent to A.

- A encrypts the message by doing (me)d ≡ m (mod pq), and thus the communication

is successful.

- Now, E has (e, pq) and me (mod pq). He won't be able to do anything with

this, because to find m, he needs φ(pq), which cannot be found through pq, and

thus the transaction is secure.

Although the RSA algorithm seems good, it takes a lot of CPU time. There's another

algorithm known as ECC, which stands for elliptic curve cryptography.

Upcoming texts are going to involve pure mathematics, we begin with the notion of

a field. A field is any set (possibly infinite) which is algebraically closed. The set of

reals, rationals, complexes are a field, while the integers are not, because division is

not closed. The field which we will be emphasizing more on is Fp, which is the set of

integers modulo p, and remember, this is indeed a field.

We define elliptic curves over Fp as

y2 = x3 + ax + b

where 0 ≤ x, y ≤ p and 4a3 + 27b2 ≠ 0. This expression is the discriminant of the

curve equation above, and we don't want it to be 0, because we don't want double

roots in our cubic.

Now to actually consider elliptic curves with the specified conditions, a field, it

must be algebraically closed. So, we need addition, multiplication and inverses to

be defined, and moreover the algebraic properties such as associativity must hold.

Remember, in all the mathematical expressions, we take modulo p to make sure that

we are talking in Fp.

We define point addition of two points A and B, as the reflection of the point

C over the x-axis, which is the intersection of the elliptic curve and the line AB.

How do we know if such a point exists? Well that's the property of the elliptic curve

we chose! For any two points on the curve, there exists a third point on the curve

such that those three points are collinear! Note that A + B = B + A here, because

the line will anyway hit C. Proving associativity is a good exercise, as well as highly

computational, hence we shall omit it in this text. For the reader's information, we

have:

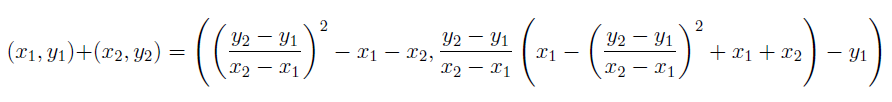

where all indices are taken modulo p.

Before we define point multiplication, let me define point doubling. Point doubling

is when you add a point P to itself, which means, the line that we're considering

is the tangent to P at the curve, and that intersects the curve at Q. Then the

reflection of Q over the x-axis is the point that is doubled.

Let's suppose we want to define kP, where k is any positive integer, and P is

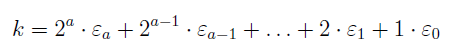

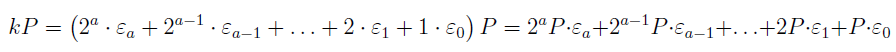

a point on the curve. We take the binary representation of k:

where a is the unique positive integer such that 2a < k ≤ 2a+1 and ϵi are all integers

in {0, 1} for all 0 ≤ i ≤ a. So, we have

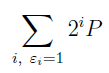

We now calculate

where 2iP is defined to be P being point-doubled i times. Then we use the associativity

property of point addition to add the entire sum one by one and finally we reach

our point Q. Again, indices are taken modulo p. Now why did we go for the binary

notation? That's because multiplying a point by 2 is well defined, and associativity

of point addition exists too, so by using binary notation we can successfully and

uniquely calculate any scalar multiple of P.

All the heavy math is done, but how are we going to use all this into the public

key private key algorithm? The experienced reader would have noticed that, if

Q = k · P, and we know (P,Q), we won't be able to find k, which means going

from (P, k) to Q is easy, but going from (P,Q) to k is very difficult. Although shor's

algorithm in quantum computing has cracked this, not all hackers have quantum

computers, so we're relatively safe. Whether this is super strong or not, it's surely a

lot more secure and less costlier than RSA algorithm.

Let's now go to the elliptic curve cryptography algorithm:

This algorithm is a slight modification of the public key private key algorithm, since

we have two private keys here.

We now have a concrete understanding towards encrypting/decrypting protocols. But

cryptography in blockchain does not end there! Assume that A makes a transaction

with B. To make sure that the transaction has not been interrupted, blockchain uses

the digital signature algorithm, which is DSA. What this algorithm does is, using a

public key which has been sent by the sender A, it will verify if the digital sigature in

the transaction matches with the output of the algorithm. And the public key has

been designed in such a way that when the transaction is interrupted, then the digital

signature would have changed. And this implies that the public key has something

to do with hash functions.

The most common digital signature algorithm, is the Elliptic Curve Digital Signature

Algorithm, or in short, ECDSA.

The algorithm has three steps, generating the public key, creating the signature

and finally verifying the signature. Let us understand them one by one:

- Generating Keys. We set the elliptic curve for this algorithm to be a multiple

of a sufficiently large prime p and let P = (x, y) be a point in the curve E.Generate a private key d ∈ [0, p - 1]. Compute Q = dP and let the public key be (E, P, p,Q).

-

Creating Signature.

To sign a message t, we have the steps

-

Verifying Signature. To verify the signature (r, s), we have the steps

- Verify that r, s ∈ [0, p - 1].

- Compute H(t'), where t' is the received message.

- Compute u = H(t')s-1 (mod p) and v = rs-1 (mod p).

Very well, how exactly do we implement this into blockchain? Well, the definition of

an electronic coin is a set of chronological digital signatures. If an interferer tries to

change the signature, then the algorithm will detect the change and thus reject the

transaction.

The Merkle Root Hash

Computer science algorithms and graph databases play a prominent role in blockchain.

When a node wants to validate any previous transaction in the ledger, it would be

way easier to search the transaction, than continuously downloading latest copies of

it, which is huge in size. Here is where Merkle root hash comes into picture. This is a

graph database algorithm which allows us to efficiently sort transactions. Merkle root

hash and B+ tree have a lot of similarities, the major similarity being the sorting

principle. We would actually like to say that merkle root hash is the general hashed

version of B+ tree, but we won't be discussing too much about the B+ tree, so let's

dive into the algorithm right away.

For brevity purposes, assume that there are only eight transactions in a block,

A,B,C,D,E, F, G,H. We have their hashes H(A),H(B),H(C),H(D). Then define

H(XY ) = H(H(X) + H(Y ))

and also H(ABCD) = H(H(AB) + H(CD)) and finally H(ABCDEFGH) =

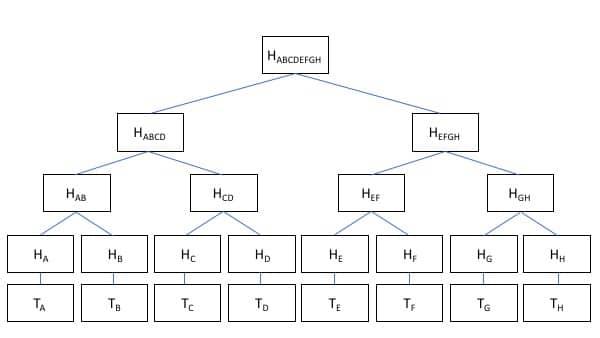

H(H(ABCD) + H(EFGH)). So the tree goes like this:

To reach to the destination of the transaction, we impart a similar idea as used in B+

tree, which is indexing. Here, the indexing is the concatenated transactions, so we

can surf through indexes and easily land onto our desired transaction.

A question is, why do we need to keep all these complicated hashes? Merkle root

hash has another job too, and it falls in the immutability category. When we said

that if a transaction is interfered, the entire block is interfered, that is because when

you change even one transaction, the merkle root of the block, which is the topmost

vertex in the graph, i.e. the vertex from which the tree begun, changes. We can also

figure out which transaction is invalid by checking the previous state of the block,

comparing the hash values in the tree. One by one we descend down the tree by

traversing through vertices whose hash values don't match and we find the transaction

that has been changed.

Smart Contracts

Smart contracts are nothing but a piece of code which execute a particular task,

provided pre-determined conditions are satisfied. In other words, they are contracts,

but automated. Let's consider this example:

Alice and bob sign a smart contract that if bitcoin's value is more than ethereum's

value in the next week, Alice shall pay 10 bitcoins, and Bob shall do the same otherwise.

Now, if the condition above is true, 10 bitcoins shall be automatically deducted

from Alice's account. If it's false, the same shall happen with Bob.

This is just a vague example that we have taken, but you may wonder, what is

the application of smart contracts in blockchain? What is the power of smart contracts?

We would say that the power of smart contracts is huge, but for now let's

understand how bitcoin smart contracts work.

When we, earlier told that an electronic coin is a chain of digital signatures, the

signatures are signed on a smart contract which then deduct the amount from the

payer's account. Which means, if A wants to send B 100 bitcoins, A signs a smart

contract which then deducts 100 bitcoins from A and transfers it to B. Now to actually

verify that the signature in the smart contract is the signature on the bitcoin, a miner

uses the digital signature algorithm and validates the payment.

The applications of smart contract in bitcoin is not that vast, but it surely is

when we change the point of focus to ethereum. Ethereum has a lot more features

apart from those of bitcoin, some with more granularity, and some are completely new.

Some basic examples are running funds. So, five people have a common ethereum

account and they have boundaries as to how much ether they can withdraw every

day. Someone has one hundred percent rights, someone has five percent rights and etc.

A very good example is the internal consensus. What happens here is, there are a set

of people (not everyone) in a common ethereum account and an internal consensus is

held to take a decision, whether to keep a particular node in their private network or

not. If majority says yes, then he is in, else he is out. Ethereum has also enabled

liquid democracy delegation.

Apart from all this, we at gboxz family believe that smart contracts can be used to

change the way this world works. Making violation of financial agreements practically

impossible, and the concept of a smart contract can be given another dimension of

extension, taking it from finance to other aspects of the world. But in this paper we

will be talking only about the financial aspects.

Talking about finance, ethereum has incorporated financial derivatives through smart

contracts.

What happens here is, when A has purchased the right, but not the obligation

to buy some shares of an ethereum account (fund). Now, if A does not want to buy

the shares, the smart contract stays silent, while if A does want to buy the shares, the

amount needed to buy the shares is automatically deducted from A and transferred

to B and A gets the shares of the company.

PBFT - A misconception

In many articles and websites across the internet, there are claims that show that

PBFT is used for deciding a state of the ledger, but there is no notion of game theory

in the bitcoin whitepaper. In the ethereum whitepaper, it is clearly written that

"The main roadblock that all pre-Bitcoin currency protocols faced is the fact that,

while there had been plenty of research on creating secure Byzantine-fault-tolerant

multiparty consensus systems for many years, all of the protocols described were

solving only half of the problem."

And it's very true, because PBFT assumes the fact that at least 75% of the nodes

are honest, but this can easily be countered when all evil nodes create thousands of alts.

When the Byzantine generals problem was published, we were talking about individual

people. One person cannot have two different faces in real life, so assumptions

like above are plausible. But in the internet era, one person can have not two, but

thousands of faces, making it practically impossible to satisfy the hypothesis.

Types of Blockchains

There are four kinds of blockchains:

- Private Blockchains

- Public Blockchains

- Permission-ed Blockchains

- Consortium Blockchains

Private blockchains are those blockchains that work within an institution. Public

blockchains are blockchains where anyone can participate. Permission-ed blockchains

are those blockchains where people that pass through certain regulators can participate,

and finally, consortium blockchains are a collaboration of private blockchains, where

the nodes that participate in the consensus are pre-defined.

Blockchain for supply chain

Now we come to the real question: how can we use blockchain for supply chain?

Blockchain can be used in supply chain in a multitude of ways:

- Getting rid of counterfeit markets

- Imparting contracting between nodes in the supply chain network

- Allows user to track their product

The first aspect is a very very sensitive one. As you can notice, many eatables and

drugs are sold at a much higher price than the original one. So, when a counterfeit

institution makes a transaction from a legit institution, the transaction is recorded,

and therefore if the counterfeit institution increases the prices, by querying his transaction,

we can figure out that the institution is counterfeit.

Contracts between nodes in the supply chain can be automated through smart

contracts, as mentioned earlier.

Users can track their product from the manufacturer all the way to the post office,

since every successful delivery is a transaction, and that allows users to feel more

secure to transact with an organization.

Conclusion

supply chain management has been evolving ever since the second world war, and

we got to see multiple drastic changes within the concept. The ways in which people

looked at supply chain management, from an absolutely disparate fragmented

functional silo, to a completely integrated robust system within all organizational

activities such as marketing and finance. In the end, as all practices surrender to

modern-day tech, the dominance of AI, IoT and Blockchain is apparent.

Technology for supply chain management is a holistic concept, AI& IoT help enhance

precision in the day to day supply chain management decisions, while Blockchain

enhances trust within an organization through immutability. Overall, supply chain

management is an evolving concept, which shall continue to evolve, for time now, and

for generations to come.

Quality Control

What is Quality?

Product quality, in intuitive terms, is a measure to how good a product is. But professionally

speaking, we define product quality as

Definition of Product Quality

Product quality is a characteristic that defines the degree of

the customer's exclamatory sense in a positive way.

Total Quality management as a whole can be divided into three different parts

- Quality by Design

- Quality Control

- Quality Improvement

According to the father of quality, Dr. Juran, TQM, that is total quality management divides

itself into eight different parts;

- Customer focus

- Customer focus

- Process centered

- Integrated systems

- Strategic & Systematic approach

- Fact based decision making

- Communication

- Continuous improvement

Let us briefly discuss each of these points:

Customer focus

Focus must be towards customer satisfaction. No matter how much

efforts have been put into creating the product, if the paradigm is not customer-centered,

then the product will not reach it's targets.

Employee involvement

Here is where MBO comes into picture, employees shall

give their best investments only if they are motivated, have rights to make decisions,

and note that the employees of a firm from all hierarchies represent the quality of the

product/products.

Process centered

Lack of set processes of a firm are the major cause of fall in quality.

The firm must have set processes integrated in it's skeleton, in order to increase quality.

Integrated system

Quality management systems play a crucial role in quality as

they unite the design of a product with business processes in ways that benefit the firm

and it's stakeholders.

Strategic & Systematic approach

In order for a firm to achieve it's business goals,

there must be quality-centered strategic plans that help the firm improve quality.

Fact based decision making

The performance of a firm must be determined through

business figures and immediate action-plans must be enforced to increase performance.

Communication

When a firm makes dramatic changes for business improvement,

each and every employee must know the changes in order to invest their time and work

appropriately that causes qualitative improvement.

Continuous improvement

Quality is all about improvement! Appropriate applications of quality principles installs kaizen slogans in the firm, thus causing drastic

improvement in quality and increases business figures in a positive manner.

Earlier, we broke quality management into three different sectors, and now we have broken it

into eight different crumbs. That means, each of these eight different crumbs belong to the

three different sector in some sense. Thus, we classify the eight crumbs into the three sectors

in the following way:

Quality by Design

- Customer focus

- Employee involvement

Quality Control

- Process centered

- Integrated systems

Quality Improvement

- Continuous improvement

- Communication

- Strategic & Systematic approach

- Fact based decision making

We are now ready to formally define TQM:

Definition of TQM

The art of managing the whole, to get a high degree of excellence.

What are the benefits that is yielded when TQM principles are applied? Here are the benefits:

- Reduce risk

- Prevent problems

- Solve problems

- Control processes

- Reduce cost of quality

- Increase productivity

- Improve supplier performance

And the most important benefit of them all is to increase quality of the firm in all aspects,

not just the quality of a product.

Although all this looks good, there is a cost that the firm must pay, which is known as

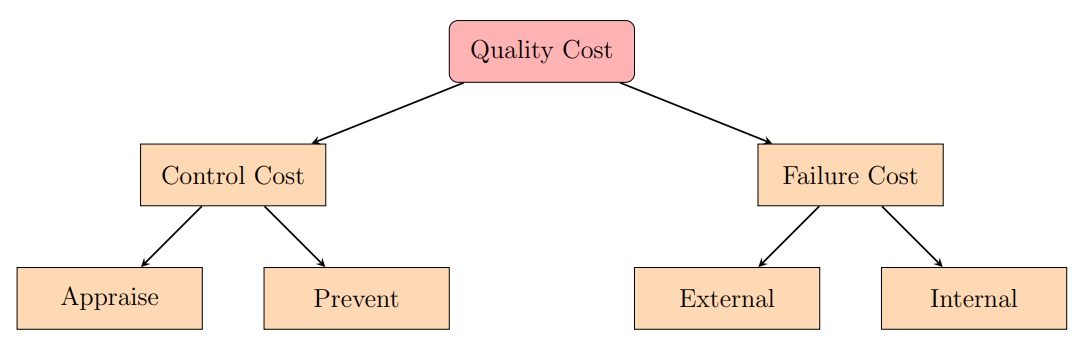

the cost of quality. This cost can be visualized as:

The cost that is payed due to poor quality of a product is known as the cost of poor quality.

An intuitive approach to minimizing cost of quality is to invest appropriately into prevention

which reduces failure cost.

The quality department is now broken into three groups, G1 who will work on quality

by design, G2 who will control quality and G3 who will improve quality, and the common goal

being to minimize cost of quality, and most importantly, cost of poor quality.

Quality Action Plan

Quality by Design

Quality by design is the art of designing a product that satisfies customers to the highest

extent. Quality by design in quality management and creating value* in marketing are very

similar, except that creating value emphasizes more towards the communication side and

quality management emphasizes more towards the delivering side. Quality by design can be

called as part two of creating value.

What exactly is the function of quality by design in a firm? Quality by design strengthens

three correlations:

- Creator's perception about customer's needs

- Expected product design and the actual design

- Design and the final product

when graphed on a scatter plot.

Quality by design works more towards preventing failures, rather than detecting and fixing

them, and as I said earlier, this reduces cost of quality and increases the customer base of the

firm.

Quality of design, is broken into five tasks, which we wil call as the 5 D's. The 5 D's

are:

- Define

- Discover

- Design

- Develop

- Deliver

Let us understand each of these points in detail.

Define

The firm begins by defining the base foundation of it's product, selecting it's

target market* and defining goals that are measurable.

The base-foundation for all industries are chosen by maximal area of expertise and

innovative base ideas that differentiate the product amongst competitive products in the same

area. For example, Zoho's CRM solutions and salesforce. Although the base ideas are the

same, Zoho did differentiate between salesforce and itself by adding new features. When it

comes to defining goals, both the service and manufacturing industries have a common list:

- Business figures

- Performance

- Customer loyalty

What is customer loyalty*? In professional terms, it is the retention capacity of a firm.

Discover

The firm must now understand the needs of the customer, provided the base foundation of the product and the target market. Which means, the design of the product is

a function of the customer needs and the base-foundation. Mathematically speaking,

Design = f(Base-foundation, Customer needs)

This makes the design of the product totally customer-centric. The design being customer centric alone is not sufficient, but the final product must be customer-centric too, which

requires processes to be customer-centric. This ensures customer-centricity in the firm, thus

embracing the first crumb of TQM.

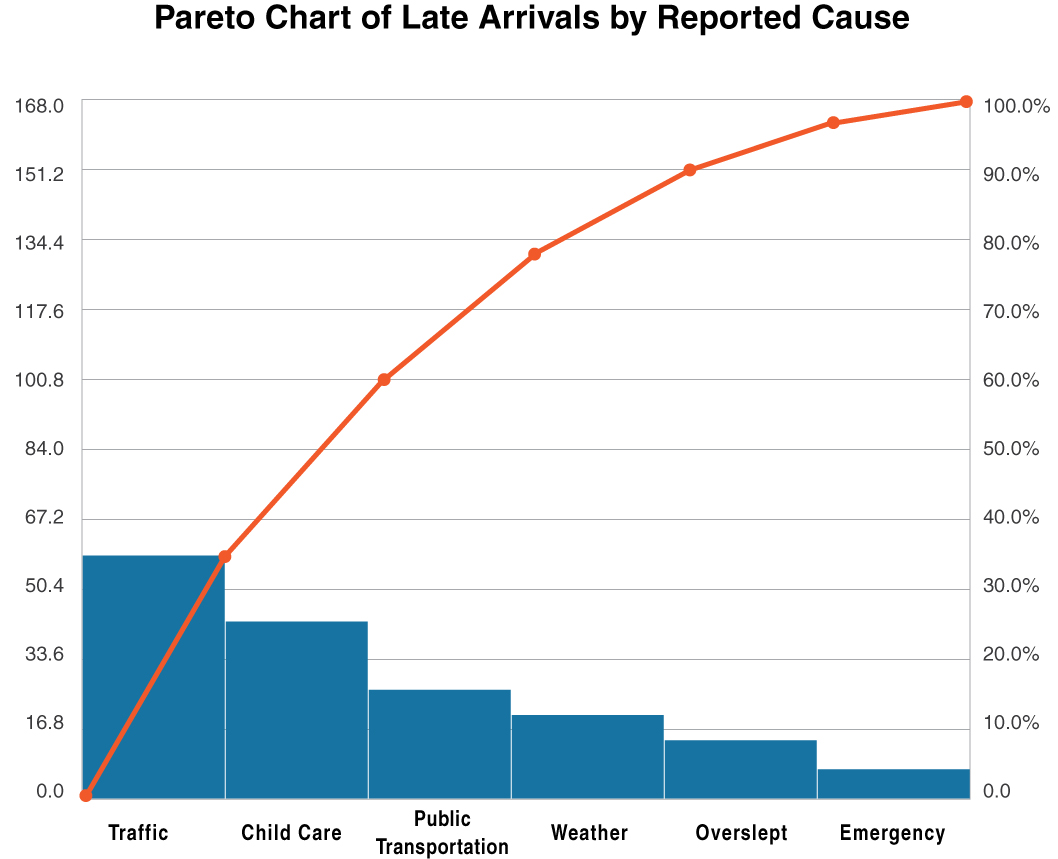

A very interesting philosophy is the Pareto principle. This principle states that a small